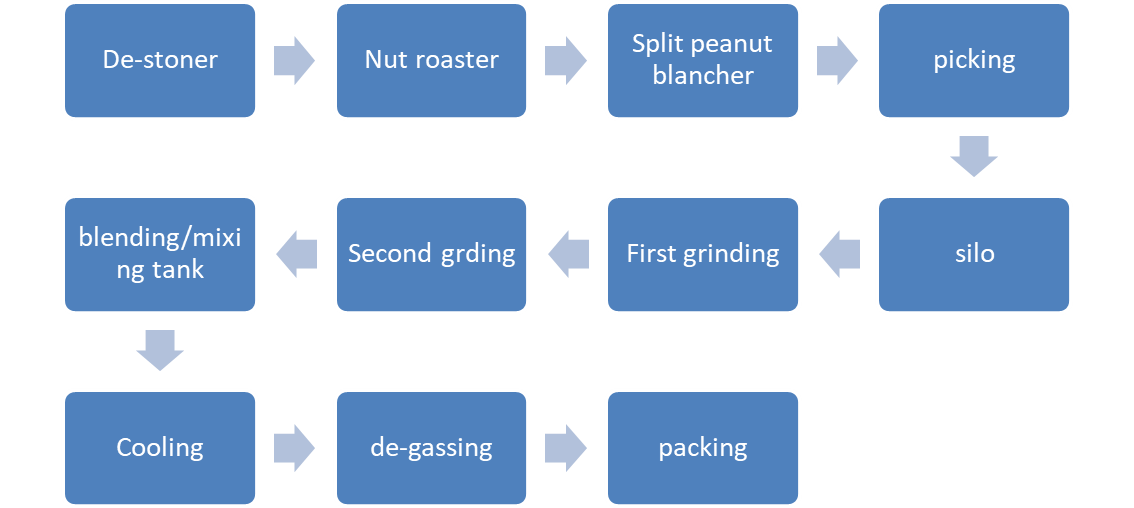

Peanut butter production line processing:

De-stoner--roasting--peeling--picking--first grinding--second grinding--mixing--degassing--cooling--packing

Peanut butter processing

Continuous belt type peanut roasting machine

The Continuous nut roaster has been designed in order to meet all the remarkable requirements existing in the dry fruit/nut roasting. In fact the roaster is particular suitable for a wide range of products such as peanuts, hazelnuts, almonds, pistachios, cashews, sunflower seeds, sweet potato and so on. The stainless steel construction allows also the processing of wet and salted products. The roasting is carried out by forced air process and this permits to obtain a plain and homogeneous product. The roaster is divided in three different sections, including feeding section, roasting section and cooling section. The product passes though all the sections transported by a conveyor belt. The heating plant operated with gaseous fuels; natural gas LPG and others; it provide with safety systems so to make the roaster working absolutely safe.

Peanu peeling machine

Split Peanut Blancher is designed to split roasted peanut into half or less half piece, under this split blanching, the red skin is taken off and collected by air cyclone. This kind of split blancher can make breakage peanut kernels

First Peanut grinding Machine

By the relative movement of the different geometric shaped stator and rotor under high-speed rotation, the material to be processed enters into the mill under the action of the Dead weight and air pressure force and centrifugal force and of the composite force, such as the strong shearing, rubbing, impact, high-frequency vibration when the material is through the annular variable gap, and then the material will be effectively dispersed, pulverized, emulsified, admixture, thereby the product with the satisfactory size and the quality will be fulfilled. The fineness grinding is reach to 40-80 meshes.

Seasoning

In this area, all flavors, such as sugar, salt, oil, stabilizer, etc. will add from the platform seasoning machine. All flavors and peanut butter will be mixed in the screw mixer and then pumping in to the second grinder.

Second Peanut grinding Machine

This peanut milling machine is suitable for processing peanut butter, chili sauce and various fruit and vegetable sauces. This precision cutting principle is a breakthrough processing method with multi-function, which can meet your needs for accurate and controlled crushing.

This peanut milling machine is designed with a reasonable sealed shell, which can effectively avoid the overflow of materials, steam and liquid. At the same time, it is made of food grade stainless steel to ensure the maximum durability and hygiene requirements

This peanut milling machine has large capacity, 24-hour operation, high sanitation, low maintenance, simple operation and easy cleaning

Blending

This tank has two layers, with three functions: mixing, cooling and temporary storage.

Peanut Butter Heat Exchanger

The butter will be pumped into cooling machine, through pipes twisted inside of cooler. It must have control temperature from cooling Temperature to 35-60C adjustable.

Degassing

Remove the air to make peanut butter more stable.

Contact: Miss Grace

Phone: +86-15818962079

E-mail: service@tradergroup.com.cn

Whatsapp:+86-15818962079

Add: RM 1607, TOWER 3, PHASE 1, ENTERPRISE SQUARE, 9 SHEUNG YUET RD., KOWLOON BAY, HONG KONG.

We chat